Silicon Carbides

High-performance silicon carbide abrasives for grinding, cutting, and polishing applications.

Products

Silicon Carbide - CF10

WIDENTA

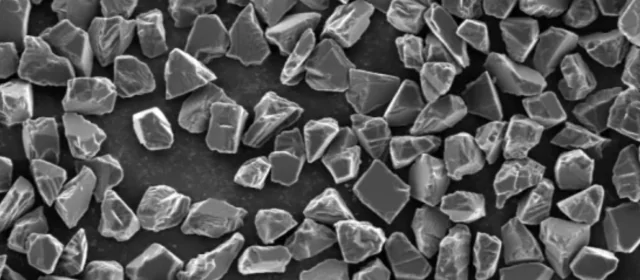

CF10 exhibits blocky grain shapes with exceptionally sharp cutting edges, making it suitable for applications in cutoff wheels, grinding wheels, and abrasive stones for processing plastic, stone, ceramic, glass, and nonferrous metals.

Overview

Experience the next level of industrial performance with Widenta silicon carbide abrasives—engineered for extreme hardness, thermal resistance, and aggressive cutting action. These advanced abrasives are designed to excel in the most demanding grinding, cutting, and polishing applications, delivering consistent results on metals, ceramics, and stone. Their sharp grain structure ensures rapid material removal and long-lasting durability, while exceptional thermal stability allows for reliable operation at high temperatures. Whether you're engaged in precision tool and die making, heavy-duty surface preparation, or high-speed production environments, Widenta silicon carbides provide the reliability, efficiency, and quality that professionals trust for critical industrial processes.

Highlights

Extreme Hardness

Outperforms conventional abrasives in cutting and grinding.

Thermal Stability

Maintains performance at high temperatures.

Features

Sharp Grain Structure

Provides aggressive cutting action and long life.

Versatile Applications

Suitable for grinding, cutting, and polishing metals, ceramics, and stone.